By now you have probably realized in researching, maybe from not putting the right search terms on Google or whichever search engine you use, that tungsten is used for far more things than just rings. While, it is clear that tungsten jewelry products have become increasingly popular, due to its characteristics of being inexpensive (in comparison to gold, silver and platinum) and durable. In fact, those same characteristics have made tungsten an ideal element to be used in many industrial processes and uses as tools for those processes.

Elements, such as tungsten, when combined with other elements, form what are known as alloys. These alloys are substances that take on the characteristics of the elements used to comprise them. Specifically, in the tool making process, tungsten is very commonly used with steel to make certain types of tools that are used in a wide variety of processes. The tungsten steel alloy is used to make a wide variety of tools.

The use of tungsten as a preferred steel alloy was not always the case. During World War II, tungsten became hard to come by as tungsten steel was being used to support the war effort. Due to the need for a replacement, molybdenum was chosen. Molybdenum is another metallic element that has very similar characteristics to tungsten and made an excellent substitute. In fact, it is still used in many elements alongside tungsten.

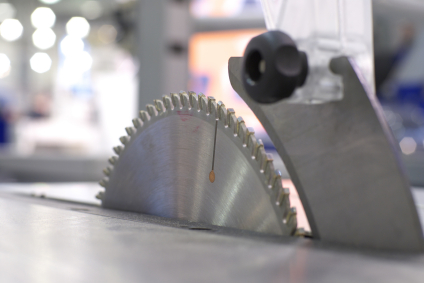

There exists what are known as high-speed tools. They are known as high speed tools as the term refers to the tools’ speed at which it cuts metals. These high speed tools are often comprised of a small percentage of tungsten, molybdenum, and vanadium, as well as smaller amounts of carbon. These high speed tools are used to make an array of cutting tools, such as saw blades, drills and gear cutters. In addition, these tools are coated with a thin layer of titanium nitride, which makes the tools last longer and even helps increase their cutting speed.

The reason tungsten is used in this type of process can be better understood by recalling some of tungsten’s characteristics. Tungsten is known to not only be very strong and durable, but also to be extremely heat resistant. When these tools, such as saw blades, are cutting through other metals or materials, there is a large amount of friction. The friction causes the cutting tools to increase in temperature. Because of the heat resistant characteristics of the tungsten element, the tools can withstand these high temperatures without compromising its purpose. In essence, the tools won’t begin to bend or break simply because of the heat, which, if not for the alloys added to the steel, could happen.

Leave A Comment